"Coil Irradiation - Coil Clean Series "

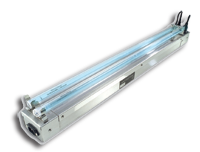

American Ultraviolet High-output CC Series utility fixtures

are designed specifically for HVAC applications. They can be mounted in various configurations for optimum pass-by air decontamination and/or to irradiate cooling coils and drain pans. Individual fixtures can be mounted to plenum walls or multiple fixtures can mount to frame assemblies that span supply ducts or cooling coils.

CC Series Applications

CC Series fixtures from American Ultraviolet are ideal for internal installation in medium to large air handling systems in commercial, industrial, health care and institutional buildings.

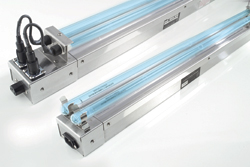

CC Series Fixtures

are offered as single and double lamp configurations with ˇ§moisture proofˇ¨ construction. They may be mounted individually; in built-up banks; or

in parallel rack-system configurations in a variety of locations, including coils, drain pans, ductwork, mixed air plenums and exhaust systems. The CC Series is available in five lengths (18ˇ¨, 24ˇ¨, 36ˇ¨, 48ˇ¨, and 60ˇ¨) and four voltage options (115, 208, 230 or 277 VAC), providing installation flexibility to accommodate virtually any system.

CC Series fixtures are designed for ˇ§moisture-proofˇ¨ applications with UVC lamps that incorporate a built-in outer quartz sleeve with protective boot on the power end for sealing purposes. Power is brought to the lamp through a waterproof connector that is securely sealed to the lamp with coated lead wires. Lamps are rated for two-year continuous operational life with approximately 20% drop in UVC output at end of lamp life.

Benefits

- Improves Indoor Air Quality (IAQ) by reducing bacteria, viruses and mold that either grow or pass through the air handling systems. Reduces the risk of cold, flu, allergies and other illness associated with air handling systems

- ˇ§Greenˇ¨ lamps contain 28mg of mercury

- Two-year (17,000 hours) guarantee on lamps with only 20% decrease in output over the two years

- Five-year, non-prorated warranty on the ballast

- Continuously cleans coils, drain pans, plenums and ducts - eliminating costly cleaning programs and the use of harmful chemicals and disinfectants

- Reduces HVAC energy costs by restoring heat transfer and net cooling capacity

- Produces no ozone or other secondary contaminants

- Plug-in connections mean no field wiring required to connect fixture to fixture when building banks of rack systems

Download Coil Clean Series Brochure

CC SERIES SPECIFICATIONS:

Every CC Series fixture is manufactured and factory assembled in the U.S.A., and

tested prior to shipment. Each assembly consists of housing, reflector, electronic

ballast(s), lamp bracket, plug-in power connectors and high output lamp(s).

FIXTURE: Housings are constructed of heavy gauge hospital grade stainless steel.

Reflectors are fabricated from the highest grade bright annealed polished stainless

steel, which has a reflectivity rate of 88% when exposed to short-wave UVC in the

range of 254 nm. All components are in one integrated assembly to maximize

serviceability.

BALLAST: The solid-state electronic ballast (furnished with this series), is a Class P

rapid start with a power factor minimum of .95. It is available as a 120, 208, 230, or 277 VAC 50/60 Hz and is designed to maximize photon production in air temperatures of 35 to 175 degrees F. Minimum ballast start temperature is minus 20 degrees F. Ballasts have a RFI - EMI rating as defined by FCC part 18A for industrial / commercial applications in regards to suppression. Ballasts are UL listed and suitable for use in air handling spaces.

LAMPS: CC Series UVC lamps are high-output (800mA), T5 tube diameter, and constructed from hard glass tubing for superior UV transmittance. Lamps are ˇ§greenˇ¨, containing 28mg of mercury (Hg) and they produce no ozone. Lamps shall retain, at

minimum, 80% of initial output after 17,000 hours of use. They are sealed for moisture protection with a water-tight connection. Electrodes are designed to maximize plasma convection and stability for superior lamp performance. Lamps are rated to produce 11.7 microwatts/cm2 per linear inch of lamp arc length at a distance of one meter. This output has been independently tested in airstreams of 400 feet per minute velocities at temperatures of 45 degrees F.

INDEPENDENT TESTING: Units are tested in accordance with the general

provisions of IES Lighting Handbook, 1981 Applications Volume, and provide output per

1" arc length of not less than 11.7 ŁgW/cm2 at 1 meter in a 400 fpm airstream of 45˘X F.

Return to HVAC Irradiation and Sterilization