![]()

![]()

UVICURE Plus

High Energy UV Integrating Radiometer

Features:

Truly compact: 4.60" (117 mm) diameter - same as a CD!

Self-contained, battery powered

Total UV dosage, Joules/cm2

Peak UV intensity, Watts/cm2

UV ranges - choice of UVA, UVB, UVC, UVV

Low battery indicator

User replaceable lithium batteries

Applications:

Measure UV curing system performance

Determine UV lamp efficiency

Establish UV level for proper curing

Meet ISO 9000 requirement

Introduction

The UVICURE Plus is a self-contained, electro-optic instrument designed to measure and display peak UV intensity and total UV energy applied to a workpiece in a UV curing system. The UVICURE Plus has a unique compact design, only 4.60 inches in diameter and 1/2 inch high, which allows it to be placed directly in most curing environments. The instrument operates successfully in the extremes of UV and thermal radiation often encountered in UV curing systems.

A carefully designed optical sensing system measures total UV dosage in a particular bandwidth. The output is converted to a digital form and then displayed on the LCD. Total UV dosage, measured in Joules/cm2, is the result of the integrated intensity during exposure time. It is how much actual UV energy was impinged on the unit from the time it encountered UV until the time the UV source was removed. The UVICURE Plus also has the distinct advantage of being able to monitor the peak intensity in Watts/cm2. This allows the operator to determine not only the total energy, but also how that energy is delivered; i.e., at what intensity.

UV POWER PUCK®

High Energy UV Integrating Radiometer

Features:

Truly compact: 4.60" (117 mm) diameter - same as a CD!

Self-contained, battery powered

Total UV dosage, Joules/cm2

Peak UV intensity, Watts/cm2

Measures four UV ranges simultaneously - UVA, UVB, UVC, UVV

Low battery indicator

User-replaceable lithium batteries

User-selectable data displays

Applications:

Measure UV curing system performance

Determine UV lamp efficiency

Establish UV level for proper curing

Measure UV spectral distribution

Meet ISO 9000 requirements

Introduction

The EIT UV Power Puck is a self-contained, electro-optic instrument designed to measure and display peak UV intensity and total UV energy used in the UV curing process. The Power Puck's unique compact design, only 4.60 inches in diameter and 1/2 inch high, allows it to be placed directly in most curing environments. The instrument operates successfully in the extremes of UV and thermal radiation often encountered in UV curing systems.

A carefully designed optical sensing system measures total UV dosage on 4 different channels simultaneously. These four different channels represent four different UV bandwidths of interest for most curing applications: UVA (320-390nm), UVB (280-320nm), UVC (250-260nm) and UVV (395-445nm). The output of the sensing system is converted to digital form and displayed on the LCD by scrolling through a user-friendly menu. Total UV dosage, measured in Joules/cm2, is the result of the integrated intensity during exposure time. It is how much actual UV energy was impinged on the unit from the time it encountered UV until the time the UV source was removed. The UV Power Puck also has the distinct advantage of being the only radiometer able to monitor the peak intensity in Watts/cm2 in each bandwidth. This allows the operator to determine not only the total energy, but also how that energy is delivered; i.e., what intensity at what wavelength.

MICROCURE Miniature UV Radiometer

Features:

Small Size: 1.3" x 0.95" x 0.25"

Lightweight: 0.33 ounces

Measures total energy density in Joules/cm2

Measures peak power density in Watts/cm2

Battery powered

High sample rate: 2000 Samples per second

Automatic operation

High temperature resistance

Applications:

UV applications requiring small size and automatic operation

Small container curing (bottles, cans, etc.)

Three-dimensional objects

Web printing

Very small conveyorized and batch applications (semiconductor printing, small

part bonders, etc.)

Statistical Process Control measurements

Introduction

EIT's MicroCureTM measurement system is comprised of two separate stand-alone items; the data collection radiometer which is placed in the ultraviolet (UV) environment to be measured, and a DataReader which reads and displays the measurement results from the radiometer.

The UV integrating radiometer is a microprocessor-based, electro-optical instrument that measures and accumulates the total UV energy that is applied to the measurement surface of the instrument. The radiometer measures the total amount of UV energy that would be impinged on a work piece passing through the curing system and the peak UV irradiance. The radiometer combines very small physical size and adaptability to address a variety of demanding physical and thermal measurement environments.

UV PowerMAPTM and UV MAP PlusTM

Advanced UV Intensity and Temperature Measurement Systems

Features and Benefits:

UV PowerMAP measures peak power density and total energy density in four spectral

regions: UVA, UVB, UVC, and UVV

UV MAP Plus measures the peak power density and total energy density for any

one channel

Collection and storage of up to I million data points for accurate UV and temperature

mapping in your system

Collected data displayed in graphical and tabular forms in the PowerView software

package

Ultra-fast, user-adjustable sampling rate - up to 2048 samples/second - ensures

high resolution even at high speeds

Detachable Optics Head - allows the use of different optics heads with the Data

Collection Unit to minimize downtime during recalibration

Offset optics for easy measurement at conveyor edge

Type J thermocouple records temperatures from 0-500°C

Low, narrow profile to allow access to most curing applications

Rugged aluminum chassis and stainless steel case

Applications:

Measure the performance of the entire UV process from the beginning of the system

to the end

Evaluate lamp focus, reflector focus, and reflector efficiency in one spectral

region with the UV MAP Plus and all four regions with the UV PowerMAP

Compare reflector materials and shapes, wavelength-specific degradation, and

uniformity over time or to other systems

Compare spectral output, degradation, and uniformity of one or more UV lamps

Measure and document substrate temperatures during the cure process to prevent

damage to temperature-sensitive materials

Track and store data for statistical quality control, regulation compliance,

or historical comparisons

Print run data to attach to work orders, reports, or ISO and FDA audits

Archive measurement data to track system performance over time

Introduction

EIT's UV PowerMAP and UV MAP Plus are advanced measurement systems that measure and store UV energy, UV irradiance, and temperature information derived from their optics and thermocouple probes in UV curing processes. The UV PowerMAP simultaneously measures all four UV channels while the UV MAP Plus measures one channel.

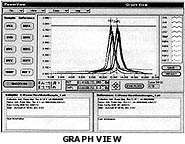

The information is transferred to a PC where it is presented in graph and data format for viewing and analysis. The information is characteristic of the same energy and irradiance that would be impinged on an actual work piece passing through the curing process.

The UV PowerMAP and the UV MAP Plus are the ultimate tools for developing, monitoring, and maintaining UV curing processes. UV formulators, raw material suppliers, and equipment suppliers can take advantage of the UV PowerMAP's ability to measure all four UV channels to develop processes that are easily transferred from a laboratory to a production environment. The UV MAP Plus monitors the one UV channel specified (A, B, C, or V) when it is ordered. The UV MAP Plus was designed more for use on a production floor, and it is an economical alternative to the UV PowerMAP. With the PowerView software, the UV PowerMAP and the UV MAP Plus offer far greater resolution, data sampling, data storage, and data manipulation than previously available in mapping systems.

Variables such as reflector materials, reflector shapes, wavelength-specific reflector degradation and uniformity, and lamp focus can be documented. Companies using multi-lamp curing systems and those that are using different spectral lamps within a system will find these radiometers indispensable.

The UV PowerMAP and UV MAP Plus systems are composed of a data collection unit, detachable optic measurement head, and PowerView software package. The units measure UV energy in Joules/cm2 and UV irradiance in Watts/cm2. With PowerView, UV sample rates are adjusted from 128 to 2048 samples per second to match resolution and information requirements.

PowerView uploads and displays the collected UV system data, unit configurations, and time/date stamps. This data is saved as a computer file that can be manipulated, customized, and exported into a spreadsheet by the user so the entire UV system can be evaluated.

MULTIBRITE®

4 Channel UV Monitoring System

MULTIBRITE® 4-Channel UV Monitoring System is an electro-optic instrument designed to monitor several UV lamps (up to four) simultaneously and sound an alarm when any of the lamps falls below a user-settable threshold. Any lamp output can be switch selected and read, as a percentage of original output, on a front panel display. The system is comprised of two major components, a Signal Conditioner and the Signal Monitor Module, both contained in the same compact enclosure.

Features:

Monitors output of 4 UV lamp sources simultaneously

Provides timely relamping information

Audible and visual alarms

Digital readout

Low output alarm

Standard linear outputs for remote monitoring

Cascadable remote alarm output

Individual channel alarm lockout

Programmable alarm enable delay

Applications:

Monitor UV lamp intensity

Reliable lamp replacement indicator

Indication of when to clean lamp reflectors

Process control measurement

Introduction

It is essential to know when to relamp in order to maintain consistent curing results. In many instances, UV lamps are either replaced at periodic intervals or when lamp degradation results in noticeable reduction in product quality and excessive waste. Since the human eye cannot determine whether or not a lamp is producing adequate levels of UV and needs to be replaced, MULTIBRITE can eliminate the guesswork. This results in saving time and money, eliminating waste, and assuring consistent product quality.

Compact Sensor

Advanced UV Monitoring System

Features:

Improved optical design to virtually eliminate solarization

Small profile for installation in tight spaces

Squared body design for easier mounting

Can be used on most lamp makes and types

Sealed optics to prevent contamination - optional air purge

Available with a "lamp on" detector

Compatible with any of EIT¹s monitoring equipment

Applications:

Monitor UV lamp intensity

Know when to perform preventive maintenance and cleaning on lamp system

Determine when to replace lamps

Use for data collection for Statistical Process Control (SPC/SQC)

Introduction

The new compact sensor from EIT is a breakthrough in UV sensor technology. It is extremely resistant to UV solarization in even the most intense UV fields. The degradation of the optical component of UV sensors in the presence of an UV field, known as solarization, is virtually eliminated in the new design.

Innovative design (patent applied for) and use of proper materials in the sensor make it possible for the sensor to view an intense UV source for thousands of hours without perceptible solarization.

The Compact Sensors are very small in size; ruggedness and hermetic sealing make it ideal for use in many industrial applications.

Optional air purge capability allows operation in less than ideal environments. The sensor's very small size lends itself to installation on the back of a lamp reflector, and its ability to withstand high UV intensities provides very long life in that position.

The Compact Sensor generates a signal proportional to the intensity of UV light impinged on the face of the sensor. This signal is fed via a 10' shielded cable to one of four display options EIT's Multibrite, Online UV Intensity Display Module, DIN Rail Mount UV Intensity Monitor, or Battery-Powered Display Module. When the UV lamps and reflectors are new, the display is set to show a 100% relative intensity. A decrease in the displayed percentage shows the gradual degradation in the UV lamp's output compared to its output when new. The relative intensity values can be converted to absolute intensity values in Watts per square centimeter by comparing the percentage to an intensity reading from an EIT radiometer.

The sensor offers great flexibility in installation. Since solarization is no longer a major concern, the sensor can be mounted to directly view any section of the lamp. Many applications allow installation where the sensor can monitor the UV light either directly from the lamp or from its reflector. In space-limited applications, the sensor can even be mounted behind the reflector.

The sensor package is sealed to protect its optics from humidity and harmful vapors. The input portion of the sensor's housing is ported to allow purging with air or nitrogen to keep the sensor window clean in dirty or hostile environments.

The Compact Sensor is available in two standard types. The CS type is the Compact Sensor only. The FS type also includes a 'lamp on' detector. Both sensor types are available in any one of four specified UV bandwidths.